Four in-house factories support our “Total Abilities”

Four in-house factories support our “Total Abilities”

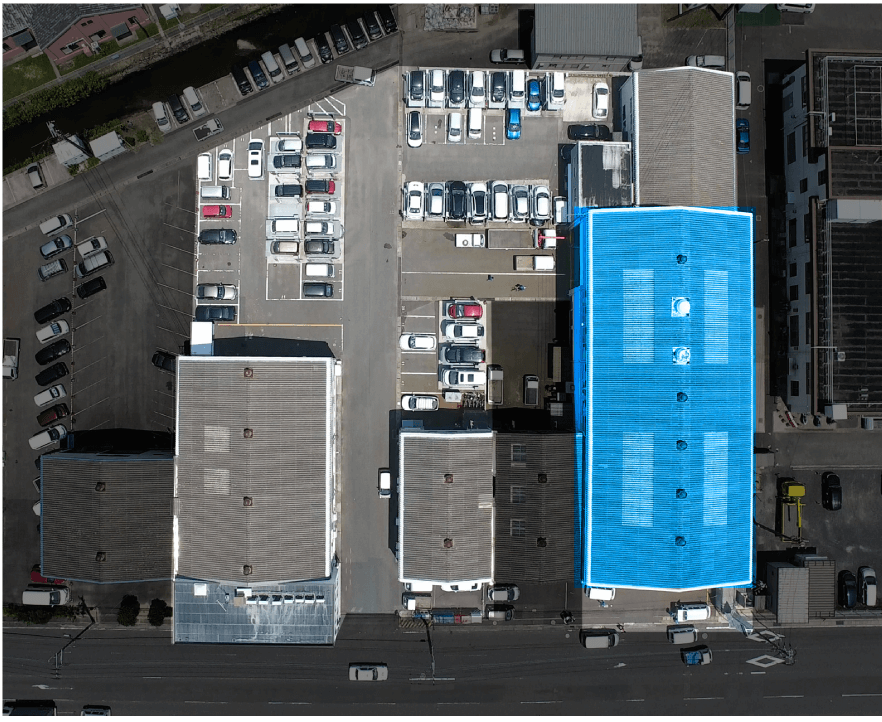

Work is done either inside the ship, or parts are brought back for detailed inspection, processing, and testing. What supports Hosei's comprehensive capabilities to reliably respond to such a wide range of ship repair needs are our four in-house factories. Let us take you on a tour of our factories, which boast a level of quality that is unprecedented in the ship repair industry.

Factory No.1

From identifying defective parts to testing.

Establishing an all-in-one system.

Establishing an all-in-one system.

From identifying defective parts to testing.

Establishing an all-in-one system.

Establishing an all-in-one system.

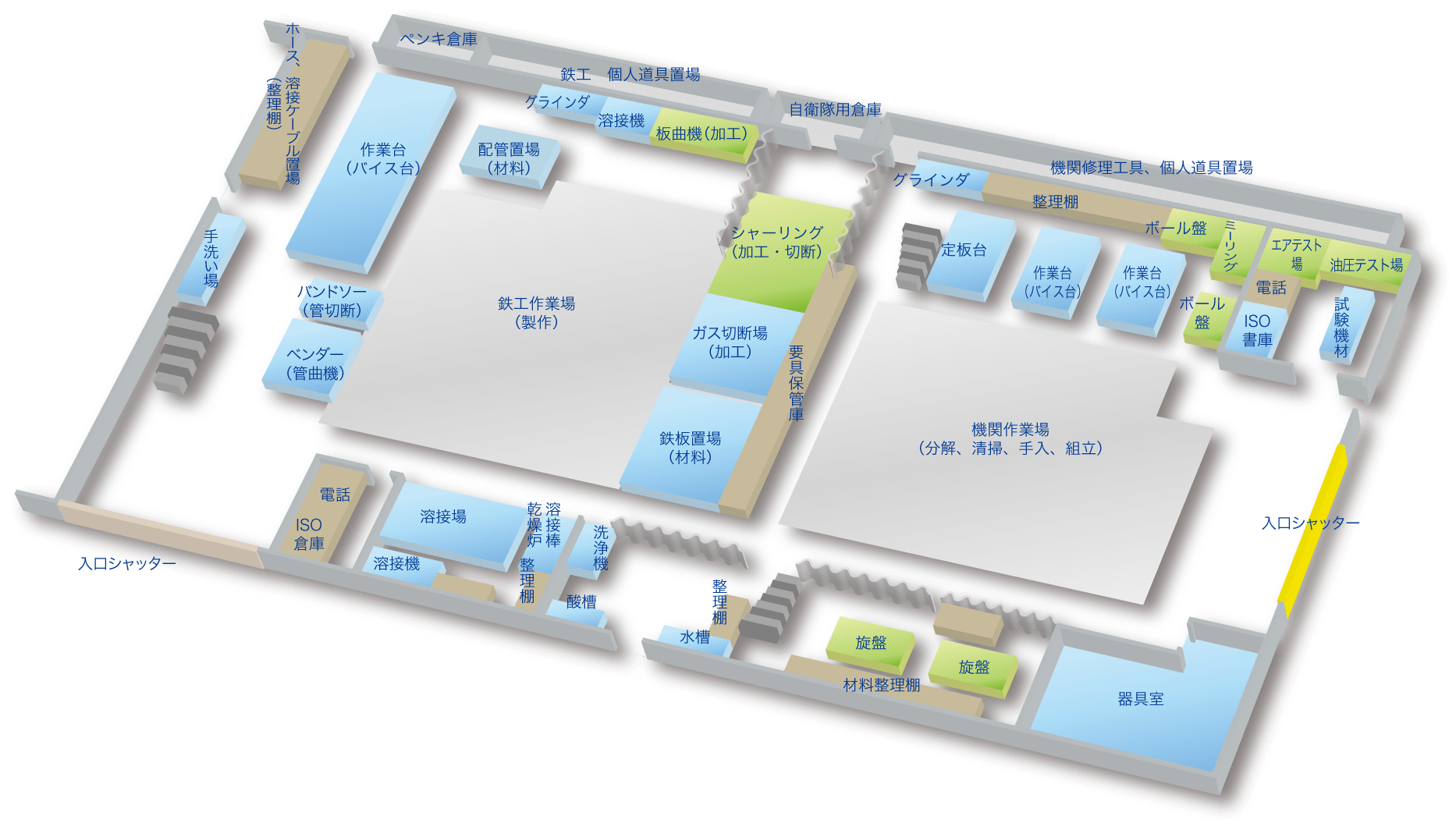

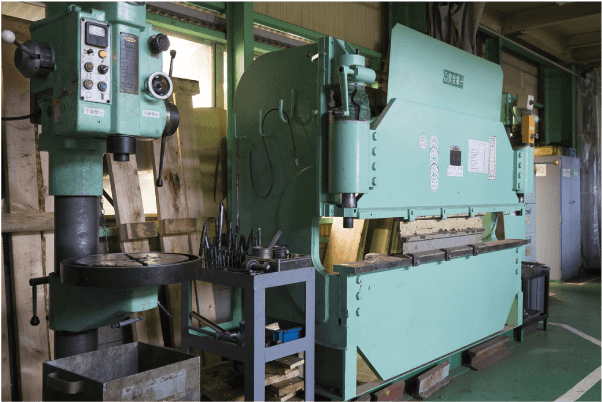

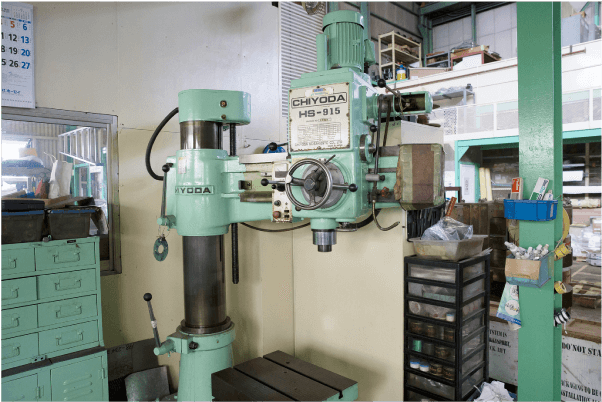

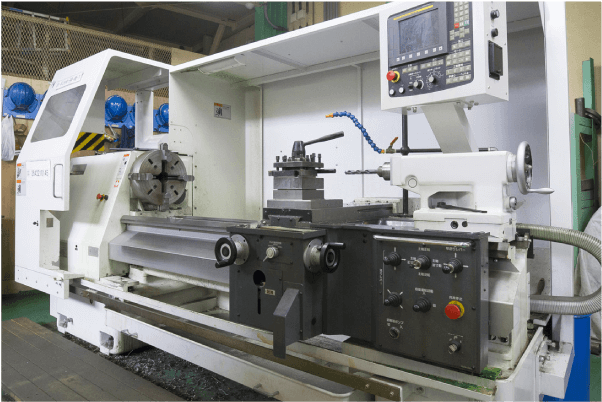

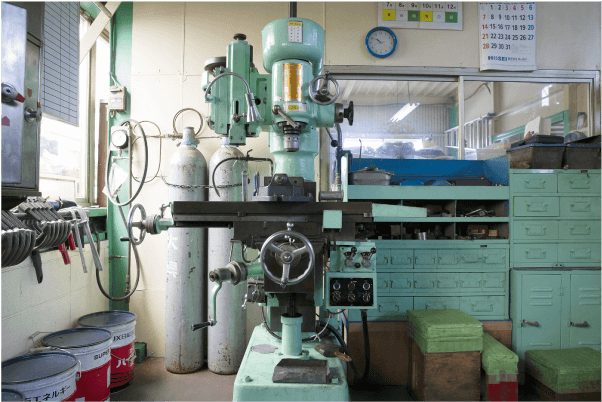

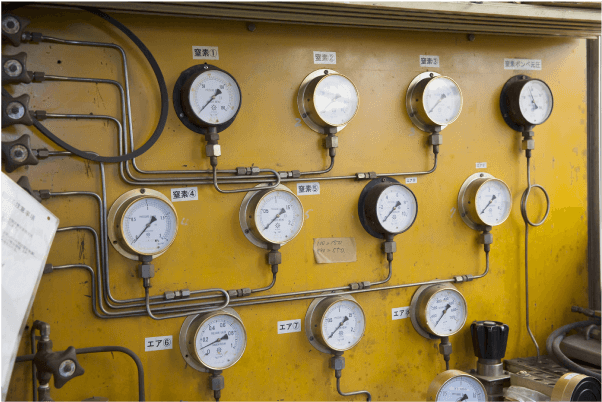

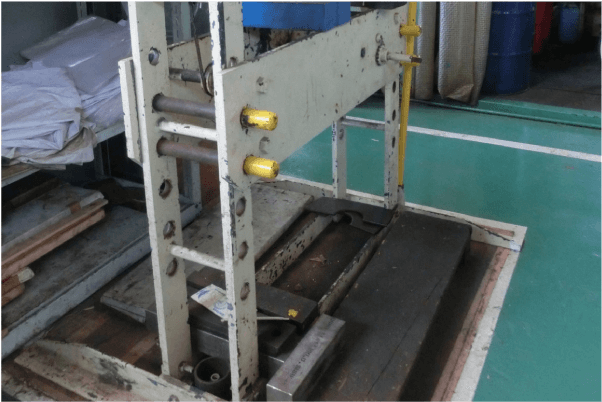

We repair ships belonging to Fleet Activities Sasebo (US naval ships) and the JFMSD, which are required to meet strict quality standards. The premise is divided into two work areas, the Ironwork Section and the Machine Section, and as a whole, an integrated all-in-one system is in place to handle the entire process of identifying defective parts, repair and maintenance, welding and fabrication, finishing, and inspection. The premises are equipped with various inspection lines consisting of hydraulic and pneumatic inspection equipment, NC lathes, milling machines (horizontal borer), drilling machines, plate bending machines, press machines and welding machines. We are also equipped with jigs and tools, so as we can manufacture even a single screw to meet the high standards required by our customers.

Plate bender

Board cutting shearing machine

Drilling machine

Cutter

Power lathe

Milling machine

Pneumatic device (Air test)

Hydraulic device (Hydraulic test)

Press machine

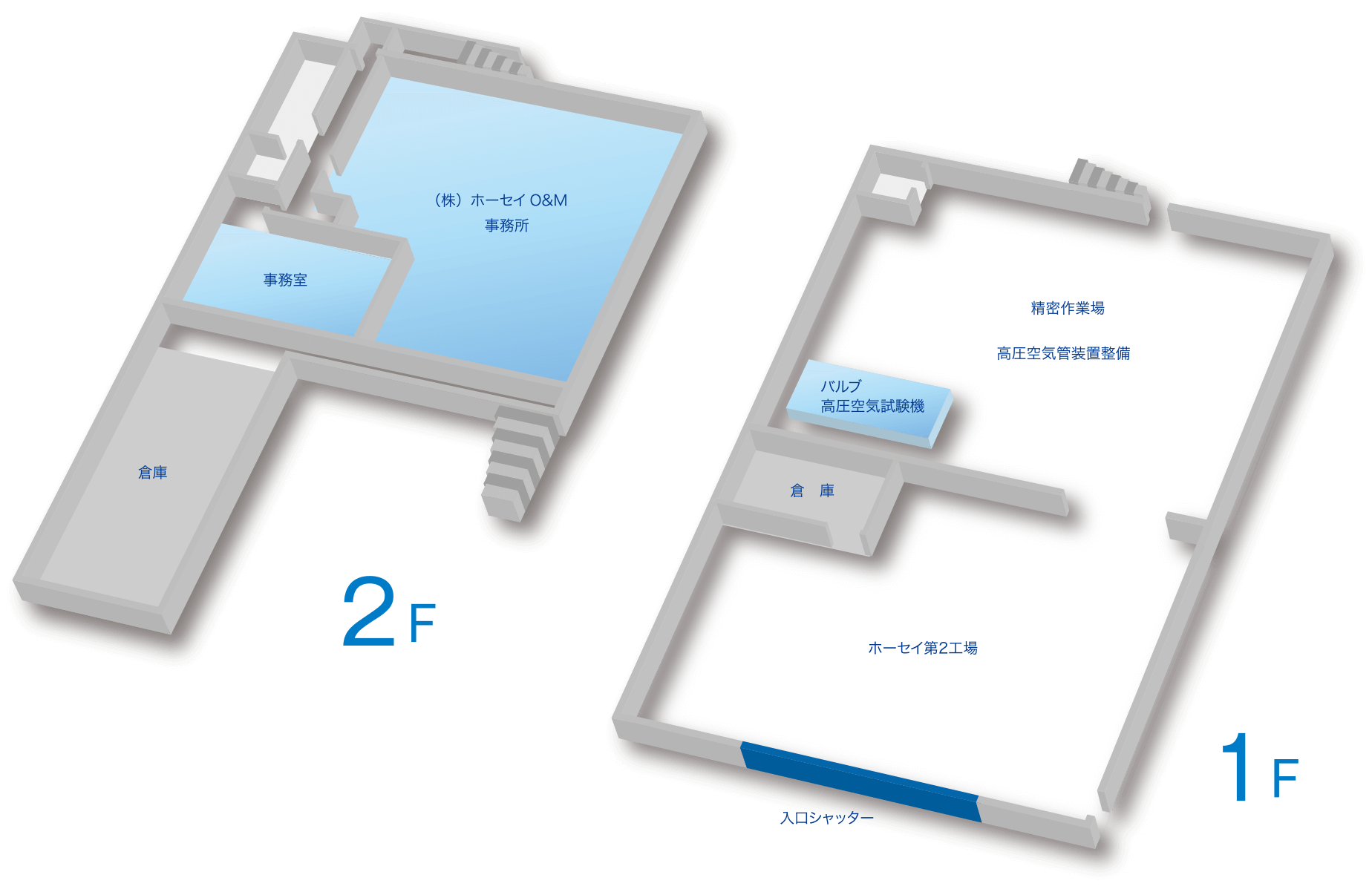

Factory No.2

Equipped with high pressure valve system.

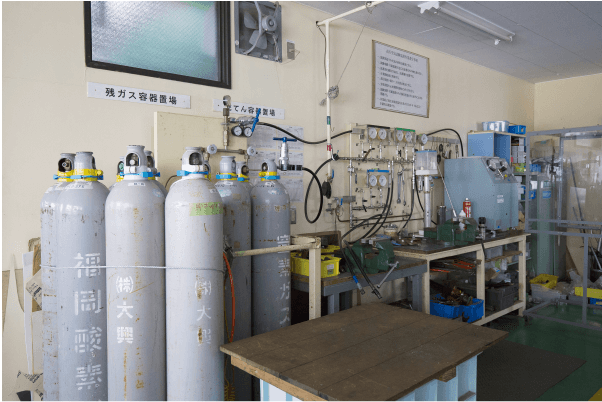

In this factory, in addition to repairing and maintaining equipment on non-combatant ships, such as ocean observation ships and transport ships belonging to the U.S. Navy’s Military Sealift Command (MSC), we also maintain and test high pressure air valves for JMSDF ships. This is our advantage since there are few factories equipped with high-pressure air valve testing equipment, including shipyards and other companies in the industry.

High pressure valve

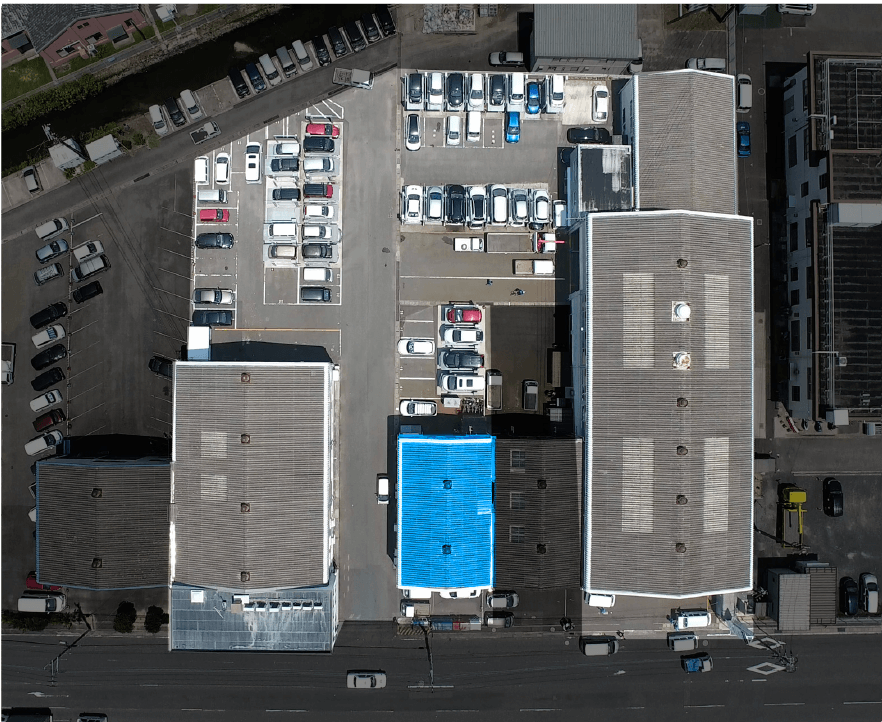

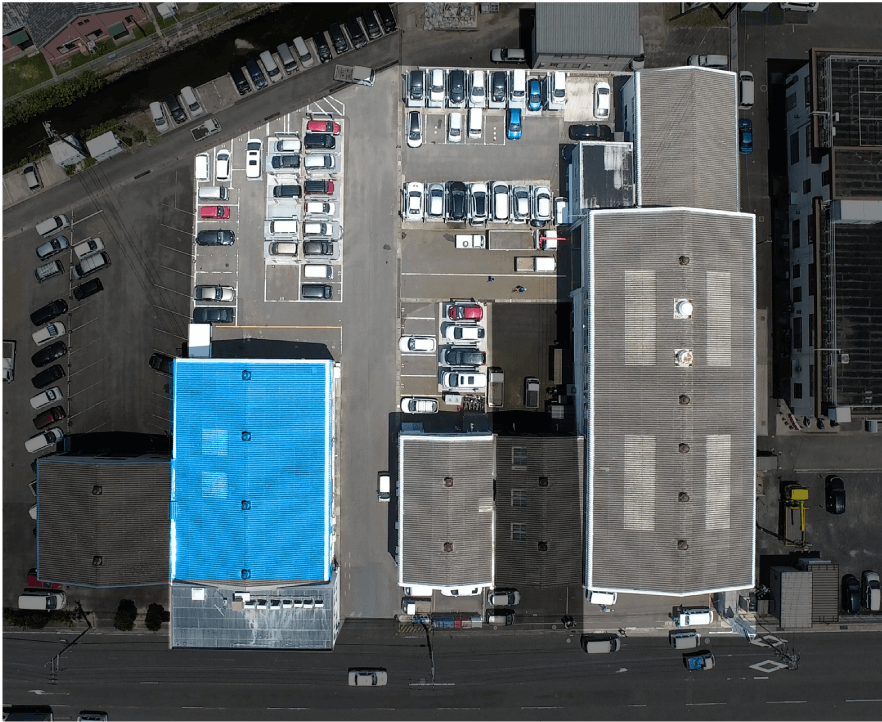

Factory No.3

Collaboration with FMSNA Japan corporation

Ficantieri Marine Systems North America Inc. (FMSNA), a U.S. Defense manufacturer, has its office in this factory, where FMSNA maintains the non-magnetic engines used on U.S. Navy Minesweepers. HOSEI provides technical support to FMSNA at their request, and the factory also serves as a place for exchange between Japanese and American engineers.